News

Beyond “Cold Weather Packages”: Embracing the Future of Anti-Icing Technologies

By Daniela Roeper, P.Eng.

In cold climates, wind turbines are able to produce more energy at lower wind speeds due to higher air density at lower temperatures. However, wind turbines face significant challenges when it comes to cold temperatures and blade icing. Icing occurs under freezing temperatures, high humidity, and precipitation, leading to the formation of ice on the blades. Icing disrupts the aerodynamics of the blades, reduces their efficiency, and poses safety risks due to mass imbalances and potential ice throws.

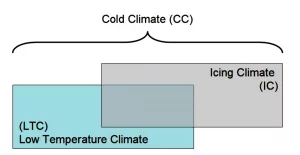

The cold climate designation refers to low temperature climates and icing climates. To determine the most efficient solution for icing issues, it is important to differentiate between low temperature climates and icing climates.

According to the IEC61400-1 standard on wind turbine design load cases, low temperature climates do not always automatically mean icing conditions and are defined by an average annual air temperature below 0°C or air temperature below -20°C for more than 9 days per year. As illustrated in Figure 1, icing climates and low temperature climates overlap.

Figure 1.

Figure 1. Illustration of the definition of cold climate according to the IEA wind task 19. Source: Best-Practices-for-Wind-Farm-Icing-and-Cold-Climate_June2020.pdf (renewablesassociation.ca)

“Cold Weather Packages” for Wind Turbines

To address icing challenges, wind turbine manufacturers have created “Cold Weather Packages” to address common issues in low temperature climates. These systems are designed to maintain optimal operating conditions to ensure turbine systems can function reliably in low temperatures. Cold weather packages typically include heaters to ensure that electrical components and the gearbox stay warm and continue to operate even if the temperature is below their rated operational range. These packages may incorporate special coatings, insulation, or operational protocols to enhance resilience and prevent issues associated with freezing temperatures.

While these packages address some issues for wind turbines in low temperature climates, they may be inadequate for the harsh conditions experienced by wind farms located in icing climates. Cold weather packages don’t usually include crucial anti-icing or blade heating systems that can prevent or remove dangerous ice from the turbine blades and ensure consistent energy production.

Effective Anti-Icing Solutions: The Role of Experts and Innovative Technologies

Anti-icing solutions have emerged as essential technology for wind farms in cold climates. These solutions utilize various methods including blade heating systems, atmospheric sensors, blade treatments, and other mechanical devices designed to prevent ice buildup and ensure the continued operation of wind turbines even during heavy icing events. It is imperative to mitigate the impact of icing in cold climates to promote optimal turbine performance and maintain safety standards across wind farms operating in challenging environments.

Effective anti-icing solutions in the wind turbine industry rely on expert-driven approaches that prioritize efficiency, sustainability, and operational reliability. One key aspect of these solutions involves the deployment of sophisticated blade heating systems managed remotely. These systems allow for proactive monitoring and response to ice buildup, enabling timely intervention to prevent performance degradation and safety risks. Additionally, blade heating systems are designed to detect ice formation and facilitate rapid ice removal when necessary.

Ice protection systems that incorporate icing sensors and specialized heating systems that heat the leading edge of the blade all the way to the tip maintain optimal blade conditions to ensure consistent turbine operation in extreme cold. By leveraging comprehensive anti-icing technologies and the expertise of industry professionals, wind farm executives can effectively safeguard their assets against the adverse effects of ice accumulation and maintain consistent energy production across their wind assets.

Addressing Challenges and Embracing Innovation

Addressing the challenges posed by ice accumulation on wind turbine blades and embracing innovation are essential steps for wind farm executives to ensure the long-term reliability and sustainability of their operations. Standard cold weather packages, while somewhat effective, have limitations in their ability to effectively monitor, prevent and remove ice on turbine blades in cold climates. These generic solutions may require additional investment in anti- and de-icing technologies, making them less sustainable in the long run.

Ongoing research and development efforts are underway to improve anti-icing technologies and overcome these limitations. Innovative approaches such as atmospheric icing detection systems and performance monitoring solutions combined with efficient blade heating systems offer promising alternatives to cookie cutter methods by providing more efficient and sustainable solutions for ice prevention and removal.

These technologies not only reduce energy consumption but also enhance operational efficiency and safety across diverse climatic conditions. It is necessary to acquire accurate, custom ice loss assessments to account for different climates and turbine types to optimize anti-icing strategies and maximize performance outcomes. By embracing innovation and investing in essential ice protection systems, wind farm executives can de-risk their operations for long-term success while minimizing operational costs and environmental impact.

Advancing Towards a Sustainable Future

When selecting a solution for your cold climate wind farm, be sure to choose a solution tailored to your specific climate and geography to optimize turbine performance, minimize downtime, and ensure long-term operational efficiency. Effectively mitigating the risks posed by icing conditions and maintaining consistent energy output helps ensure a positive return on investment.

Challenges posed by icing on wind turbines and implementing customized, effective solutions beyond standard cold weather packages are paramount for wind farm executives to safeguard their assets and ensure uninterrupted energy production.