News

Maximizing Wind Turbine Efficiency: Understanding the Capacity Factor

Wind energy, a vital component of the renewable energy industry, relies on the Wind Turbine Capacity Factor to gauge efficiency. Understanding this measurement is crucial for those managing wind farms, particularly in cold climates where unique challenges, such as icing events, can impact performance. The Wind Turbine Capacity Factor is the average power output divided by the maximum power capability.

The capacity factor is calculated as follows:

Daniela Roeper

Vice President BorealisWind

Actual output / maximum possible output = Capacity Factor

For example, if we have a 3MW turbine, its maximum possible output would be 3MW x 365 days x 24 hours a day, which is 26,280 MWh per year. The actual output is dependent on a variety of factors including wind speeds, maintenance downtime, downtime due to the environment (e.g. icing events), or downtime due to errors or malfunctions. Considering these factors, the actual output may have been 9695 MWh. If we input this information into the equation, you would have a capacity factor of 36.89%.

Example:

9,695 MWh / 26,280 MWh = 36.89% Capacity

The Wind Turbine Capacity Factor is calculated as the ratio of actual energy production to the maximum possible output over a given period. It provides a percentage that reflects how effectively a turbine converts wind energy into electricity. A higher Capacity Factor indicates more consistent and optimal performance, while fluctuations in wind conditions or maintenance issues can lead to a lower Capacity Factor.

Calculated over time, it provides a comprehensive assessment of a turbine’s performance. The capacity factor considers the entire duration, capturing both peak and average outputs, revealing how efficiently a turbine operates by highlighting periods of low or zero output.

Importance of Wind Turbine Capacity Factor

Recognizing the critical role the Capacity Factor plays in evaluating turbine efficiency is essential for those overseeing wind farm operations. It goes beyond conventional metrics, offering a holistic view of a turbine’s contribution to energy generation. Understanding the role of the Capacity Factor can help improve understanding of the actual energy generation potential. This means translating theoretical capacity into tangible, reliable energy outputs.

Wind Turbine Capacity Factor in Cold Climate Wind Farms

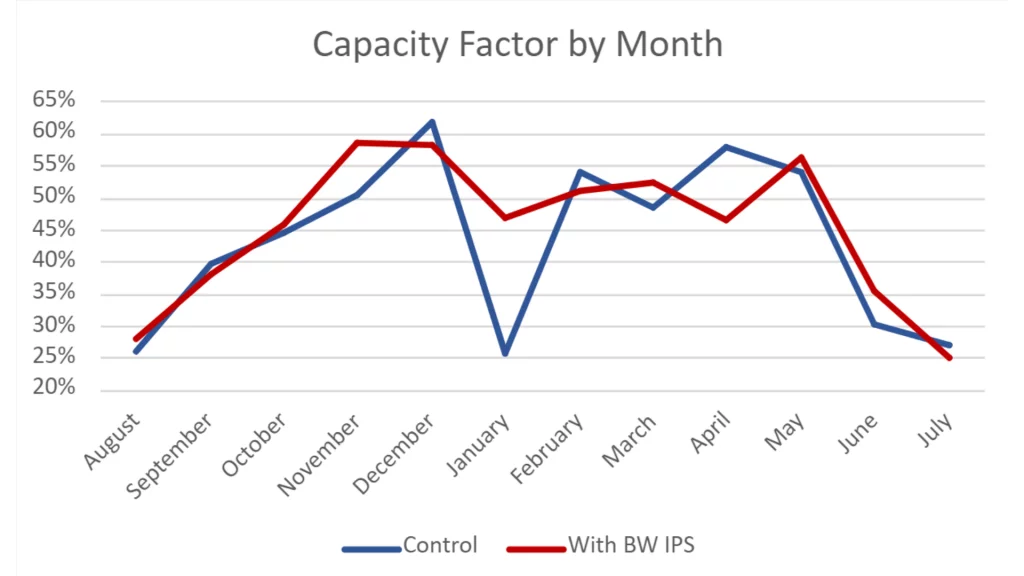

Cold climates experience a distinctive seasonal variation in wind turbine output. Surprisingly, winter yields higher energy production compared to the summer, due to higher wind speeds and higher air density, presenting an opportunity to harness peak performance. Data from Icetek, an Ice Conditions Monitoring System company in Canada, illustrates the contrast between summer and winter, and the difference between a turbine with the BorealisWind IPS and without.

The graph presents several interesting data points. First, it highlights the significant variation of the capacity factor from summer to winter. The average winter capacity factor from these turbines is 50% whereas the summer capacity factor is only 35%. This is predominantly due to the higher wind speeds seen in the winter months compared to the summer months but can also be attributed to the higher air density in the colder months. Second, you can see the difference in the capacity factor for the turbine with the BorealisWind Ice Protection System (IPS), especially in January where there is a 21% lower capacity factor for the turbine without the IPS.

For those managing wind farm production in cold climates, understanding these fluctuations is pivotal. Some wind farms have minimum energy production requirements, and comprehending the seasonal variations helps ensure these benchmarks are met, impacting revenue. Additionally, this knowledge aids in planning optimal timing to strategically shut down turbines for maintenance without compromising overall energy production efficiency.

How Icing Events Impact Wind Turbine Capacity Factor

Icing events pose a significant threat to wind turbines, affecting the Capacity Factor. Prioritizing strategies to prevent and manage icing is essential, ensuring optimal energy production. The risks associated with icing extend beyond immediate power losses. Grappling with maintenance challenges, potential equipment damage, and prolonged periods of reduced capacity is a reality. Implementing effective strategies to combat icing is essential. From advanced de-icing technologies to proactive maintenance, these solutions safeguard the Wind Turbine Capacity Factor in cold climates.

Consistently evaluating the Wind Turbine Capacity Factor is imperative, recognizing its pivotal role in sustaining wind farm efficiency. The conclusion underscores the imperative of addressing icing events for optimal energy production, highlighting the symbiotic relationship between Capacity Factor and effective management of cold climate challenges. Exploring and adopting innovative solutions outlined in the resources is encouraged, ensuring sustained performance in the face of icing challenges.