Blogs

Preventing Turbine Damage: How Ice Build-Up Compromises Turbine Safety and Integrity

Wind turbines are designed to harness renewable energy, but turbines in cold climates endure harsh conditions that may compromise their ability to operate effectively year-round. In cold climates, ice build-up on turbine blades poses significant challenges, threatening the safety, reputation, and financial performance of wind farms. Let’s examine the risks of ice accumulation, its impact on turbine components, and the preventative measures that can mitigate damage and protect your investment.

Daniela Roeper, P.Eng.

Vice President BorealisWind

The Impact of Ice Build-Up on Turbine Blades

Ice accumulation on turbine blades disrupts the aerodynamic balance of the rotor, creating uneven weight distribution. This imbalance forces the turbine to operate under irregular stress, causing excessive vibrations and wear on critical components, including the drivetrain, gearbox, generator, bearings, and even the tower and foundation structure.

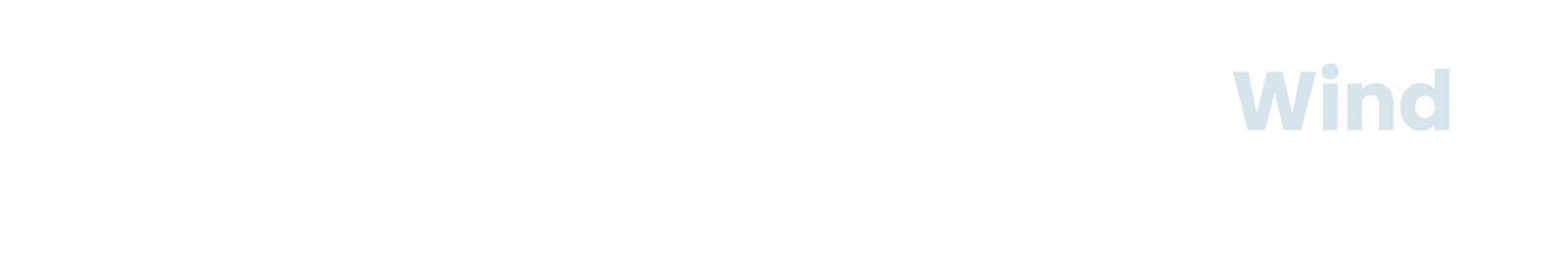

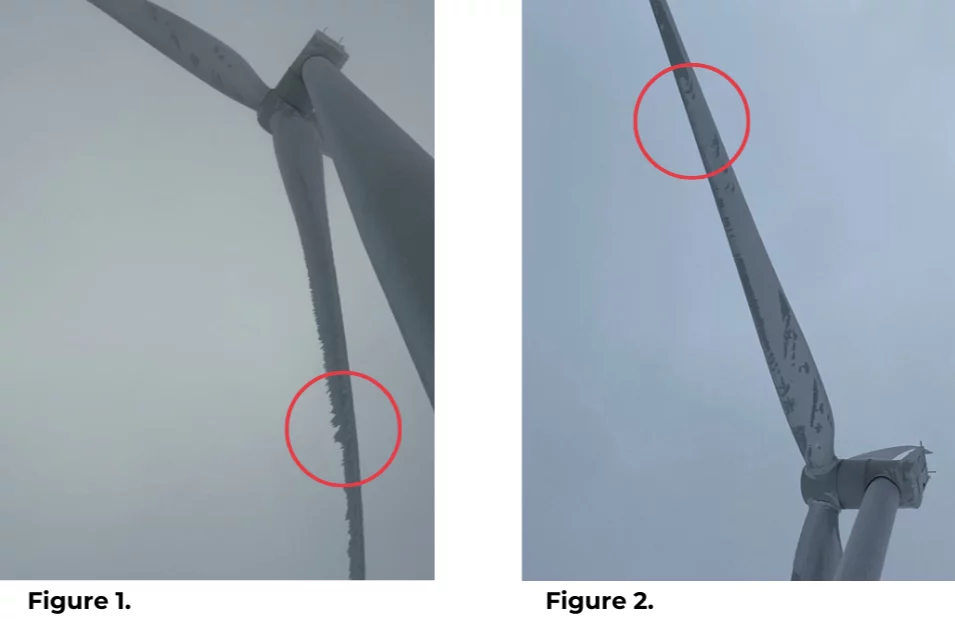

In extreme cases, these imbalances can trigger tower oscillation errors, leading the turbine to shut down for safety reasons. Tower oscillation errors typically occur when there is movement in the turbine tower or foundation. For example, a turbine experiencing heavy icing on one blade can experience tower oscillations that cause the turbine to shut down (Figure 1.) Within 24 hours of installing an anti-icing system on a turbine experiencing significant ice build-up, over a foot of ice melted, and the turbine resumed normal operation. (Figure 2.)

Structural Damage Risks

Prolonged exposure to ice build-up can severely compromise the integrity of turbine blades. Ice adds substantial weight to the blades, increasing the risk of cracks, deformation, or delamination. These structural weaknesses escalate over time, potentially leading to catastrophic failures, such as blade detachment or significant damage to the drivetrain and tower.

Unaddressed, this prolonged stress can also harm the turbine’s mechanical components, compounding repair costs and downtime. Preventing ice accumulation is critical to ensuring the long-term reliability of turbine blades and other key components.

Safety Concerns and Liability

Ice throw—where chunks of ice are flung from rotating turbine blades—is a significant safety hazard for technicians, nearby property, and even public roads or trails. Depending on wind speeds and blade size, ice can be thrown hundreds of meters, posing risks to people and infrastructure.

For wind farm operators, ice throw incidents create not only safety concerns but also potential liability. If ice causes injury or damage, operators may face lawsuits, increased insurance premiums, or reputational harm. Proactively addressing ice risks is essential for mitigating these liabilities.

The Financial Costs of Structural Damage

The financial repercussions of ice-related turbine damage extend far beyond the cost of repairs. Replacing or repairing damaged blades, gearboxes, or towers can cost hundreds of thousands of Euros per incident. Downtime caused by icing further compounds these losses, as turbines remain inactive during high-energy demand periods.

Additionally, recurring ice-related damage increases long-term costs, including higher insurance premiums and operational expenses. The financial burden of unaddressed icing can erode the profitability of a wind farm, making preventative measures a necessity for financial sustainability.

Long-Term Implications for Asset Value

Recurring damage caused by ice build-up not only reduces the lifespan of turbines but also lowers their resale and asset value. A turbine with a history of icing-related repairs is less attractive to potential buyers or investors, as it signals higher maintenance costs and lower reliability.

By preventing ice accumulation, wind farm operators can preserve the long-term value of their assets. Ensuring that turbines remain in optimal condition enhances their ROI and makes them more viable for resale or continued operation.

Preventative Measures to Mitigate Damage

Comprehensive ice protection systems offer a proactive solution to protect turbine blades from icing. These systems use advanced sensors to detect icing conditions and deploy targeted heating to prevent ice accumulation on critical blade areas, such as the leading edge and tip.

In addition to safeguarding structural integrity, ice protection systems ensure consistent energy production by minimizing downtime caused by ice-related shutdowns. They also reduce the risk of ice throw, enhancing safety for personnel and nearby property.

Routine turbine maintenance complements these systems by ensuring that all components function efficiently. Predictive maintenance included in service agreements or vibration analysis and SCADA monitoring, help identify potential issues early, preventing costly breakdowns and maximizing turbine performance.

Protecting wind turbines from ice build-up is essential to maintaining safety, operational efficiency, and financial stability. Ice accumulation compromises turbine safety and integrity, leading to structural damage, safety risks, financial losses, and reduced asset value. By investing in comprehensive ice protection systems and routine maintenance, wind farm operators can mitigate these risks, ensuring their turbines operate efficiently and profitably for years to come.

Proactively addressing turbine damage caused by ice isn’t just about preventing problems—it’s about protecting your investment and securing the future of renewable energy.

Additional Information

4 Ways to Protect Your Wind Farm Property and Assets from Ice Damage

Use Case: Wind Farm in Sweden Could Earn 67% ROI with Ice Protection