Blogs

Prepare Now for Next Winter: Spring Planning for Wind Turbine Icing Protection

Wind turbine icing isn’t just a seasonal inconvenience – it leads to reduced energy production, increased maintenance costs, and safety risks for wind farms. The accumulation of ice on turbine blades can reduce annual energy production (AEP) by 3% to 20%, depending on severity and location, according to the National Renewable Energy Laboratory (NREL). And the financial impact doesn’t stop there. Icing events can cause turbines to shut down entirely or operate inefficiently, compounding losses during high-demand periods when energy prices are often at their peak.

Daniela Roeper, P.Eng.

Vice President BorealisWind

With proactive planning and the right systems in place, many of these challenges can be prevented. Spring is the ideal time to plan for implementing an ice protection system so that your wind farm is fully prepared in time for the next winter season. Here’s why timing matters and how you can take full advantage of the warmer months to ensure consistent performance all year long.

Why You Need to Get Started in the Spring

Late summer and autumn can have unpredictable weather and tight schedules, while spring and early summer typically have ideal conditions for turbine access and equipment installation. Mild temperatures and fewer weather-related delays mean crews can work more safely and efficiently. In fact, the summer weather window is often the best opportunity of the year for field service teams to complete blade modifications or installations without compromising project timelines.

Installing early also provides the opportunity to adjust and test your ice protection system well ahead of winter. By the time the first cold front arrives, your system will be tested, fully operational, and ready to protect your assets.

The Right Technology for Your Turbine and Climate

Not all wind turbines experience the same icing risks—and not all ice protection systems are created equal. That’s why you need to evaluate which technology is best suited for your wind farm based on your turbine’s blade structure, size, and local icing class. (Source: IEA WIceAtlas)

Wind farms in Icing Class 2 or higher may face frequent or prolonged icing events that require high-performance, low-maintenance solutions. By starting your planning process in spring, you’ll have the time to consult with experts, select the right system, and design a solution tailored to your specific operating environment.

Minimize Downtime and Installation Disruptions

Spring and early summer are also strategic from a scheduling perspective. Turbines are typically experience lower loads during these months, making it easier to coordinate brief shutdowns for installation without significantly impacting production.

Proactive planning also means you’re less likely to run into scheduling issues caused by the high demand for skilled technicians later in the year. And if your wind farm already has planned maintenance downtime during the warmer months, ice protection installation can be coordinated in parallel—minimizing disruption and reducing overall costs.

And when it comes to the bottom line, spring installations prevent missed energy production during the winter, when both demand and prices are highest. (Source: U.S. Energy Information Administration – Seasonal Electricity Prices)

Ensure Safety, Compliance, and Long-Term Performance

Installing an ice protection system isn’t just about preparing for next winter, it’s also an opportunity to review your wind farm’s safety procedures, maintenance strategies, and performance goals.

Spring installations give your team time to:

- Coordinate with your OEM to ensure compliance with turbine specifications.

- Conduct safety assessments and prepare work permits.

- Train staff on how to monitor and maintain the system throughout the winter.

- Validate and optimize system performance using real-time monitoring tools.

Taking these steps during a low-risk season helps reduce the likelihood of issues arising when the stakes are higher in winter.

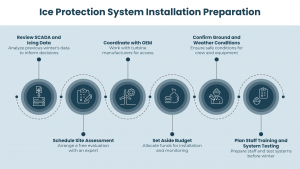

Spring Installation Planning Checklist

Use this checklist to guide your planning and ensure a successful installation:

- Review SCADA and meteorological data to assess icing-related losses from the past season.

- Schedule a site assessment with an ice protection expert.

- Confirm blade type, turbine model, and icing class to determine appropriate technology.

- Coordinate installation dates with your OEM or operations team.

- Allocate budget for installation and ongoing service/monitoring (CapEx or OpEx, depending on your service model).

- Ensure ground and lift equipment access for installation teams.

- Train relevant staff on system operation and maintenance.

- Plan time for performance validation and system monitoring before icing season.

A Smart Investment Starts with Smart Timing

Waiting until fall to start thinking about ice protection can put your operations at risk. Spring and early summer offer the best window for safe, effective, and timely installation – giving you the confidence that your turbines will perform reliably throughout the winter.

By taking action now, you protect your turbines from unnecessary downtime, avoid safety hazards, and ensure consistent energy production when it matters most.

Ready to protect your wind farm for the next winter season? Contact us today to schedule a site assessment or learn more about installation planning.

Additional Information

VIDEO: How does downtime due to icing effect energy production?

Read use cases to see how much ice protection could save your wind farm