Use Cases

Canadian Wind Farm Could Recover 70% of Icing Losses with Ice Mitigation

Background

In Canada’s winter conditions, where temperatures can plummet to -50°C and wind chills create severe operational challenges, keeping wind turbines running efficiently becomes a critical task. Ice buildup on turbine blades not only reduces energy output but also poses safety risks due to falling ice, endangering people and property nearby. By adopting comprehensive ice protection solutions, wind farms can ensure consistent energy production throughout the harshest months while mitigating the risks of ice-related inefficiencies and hazards. These systems are essential for maximizing year-round energy generation and safeguarding both assets and personnel.

Problem: 8% Loss of Annual Energy Production (AEP)

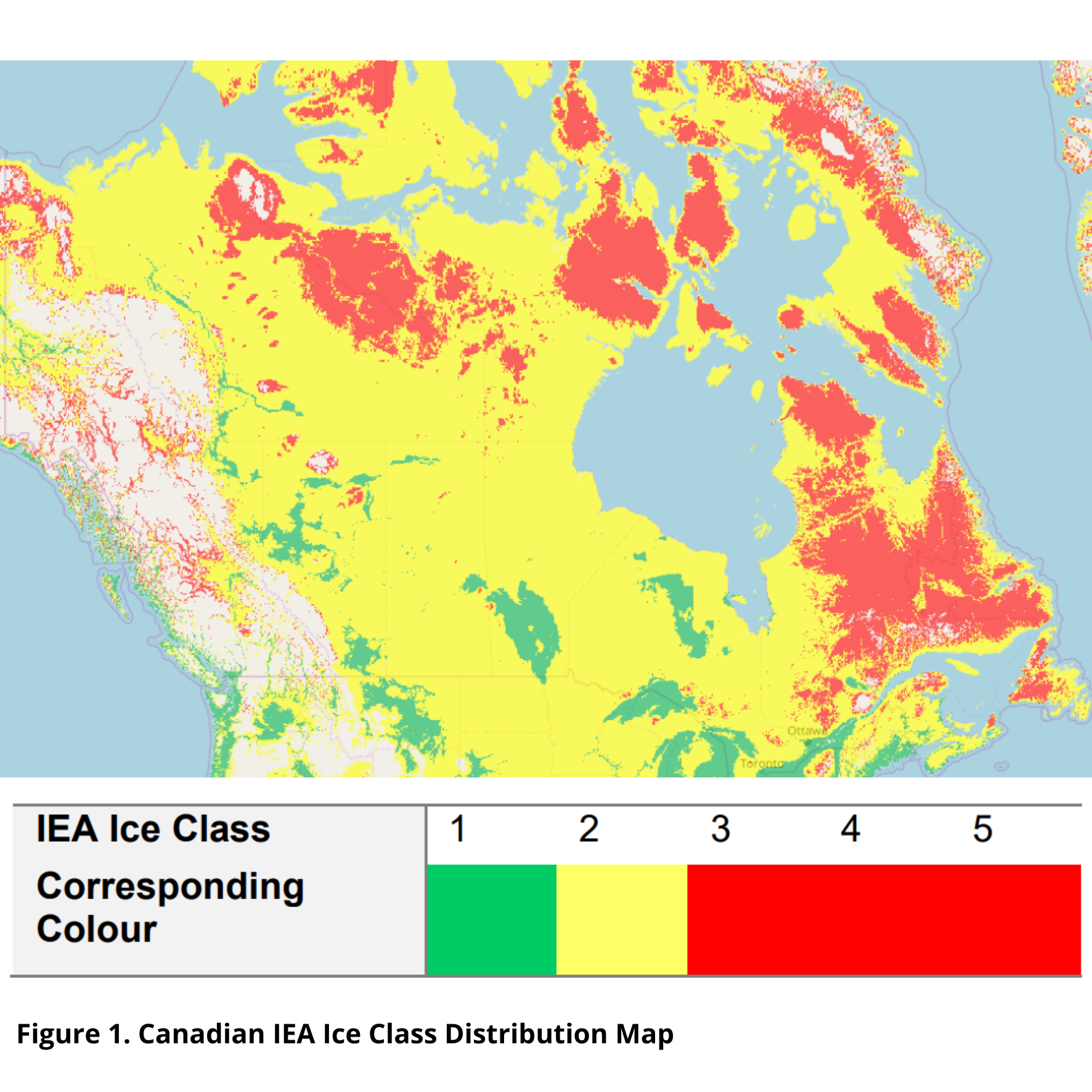

For a wind farm in Canada with Icing Class 2 conditions (Figure 1), ice accumulation on turbine blades can result in an 3% loss in annual energy production (AEP). For a 3 MW turbine operating at a 40% capacity factor, this equates to a significant annual revenue loss. Generic solutions like cold weather packages or blade coatings often fail to address severe icing, leading to costly downtime and potential safety risks from ice throw.

Solution: Comprehensive Ice Protection

The BorealisWind Ice Protection System (IPS) is a comprehensive solution that uses advanced meteorological sensors to detect icing conditions early and activate the blade heating system, effectively preventing ice formation and ensuring continuous turbine operation in harsh winter conditions.

3

2

40%

$90

8760

Results: Significant Recovery of Lost Energy

Within the first year of installing the IPS, a wind farm in eastern Canada could earn a return on investment of 32%!

By effectively mitigating an estimated 70% of icing-related AEP losses, the wind farm could earn an additional $52,980 in revenue per turbine. With no capital expenses or maintenance costs to consider the IPS can mitigate icing-related AEP losses and increase revenue within the first year of installation.

3%

70%

$52,980

1st year

Installing comprehensive ice protection on your wind farm can maximize turbine performance and drive revenue during the most important time of year.